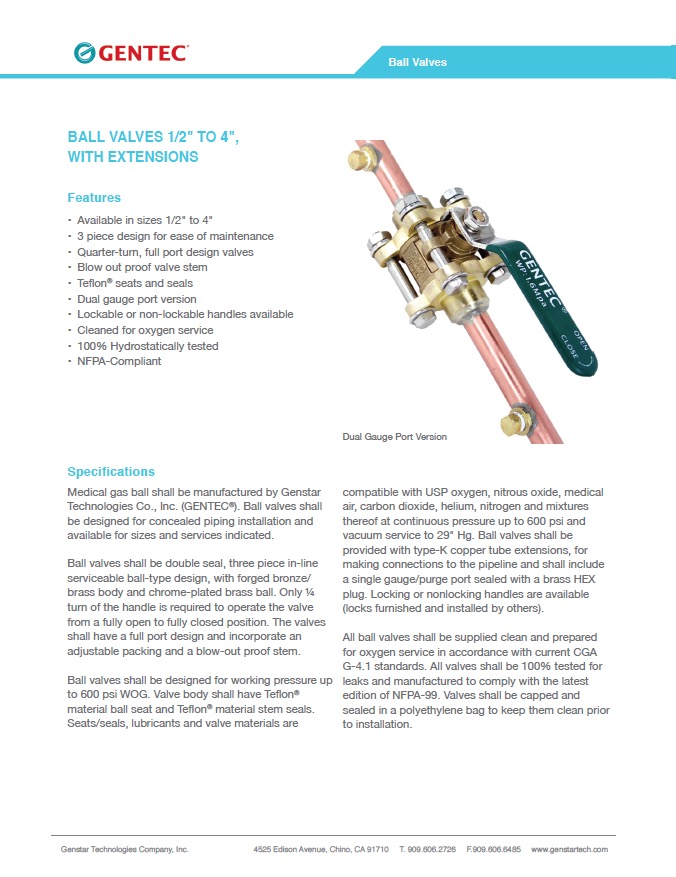

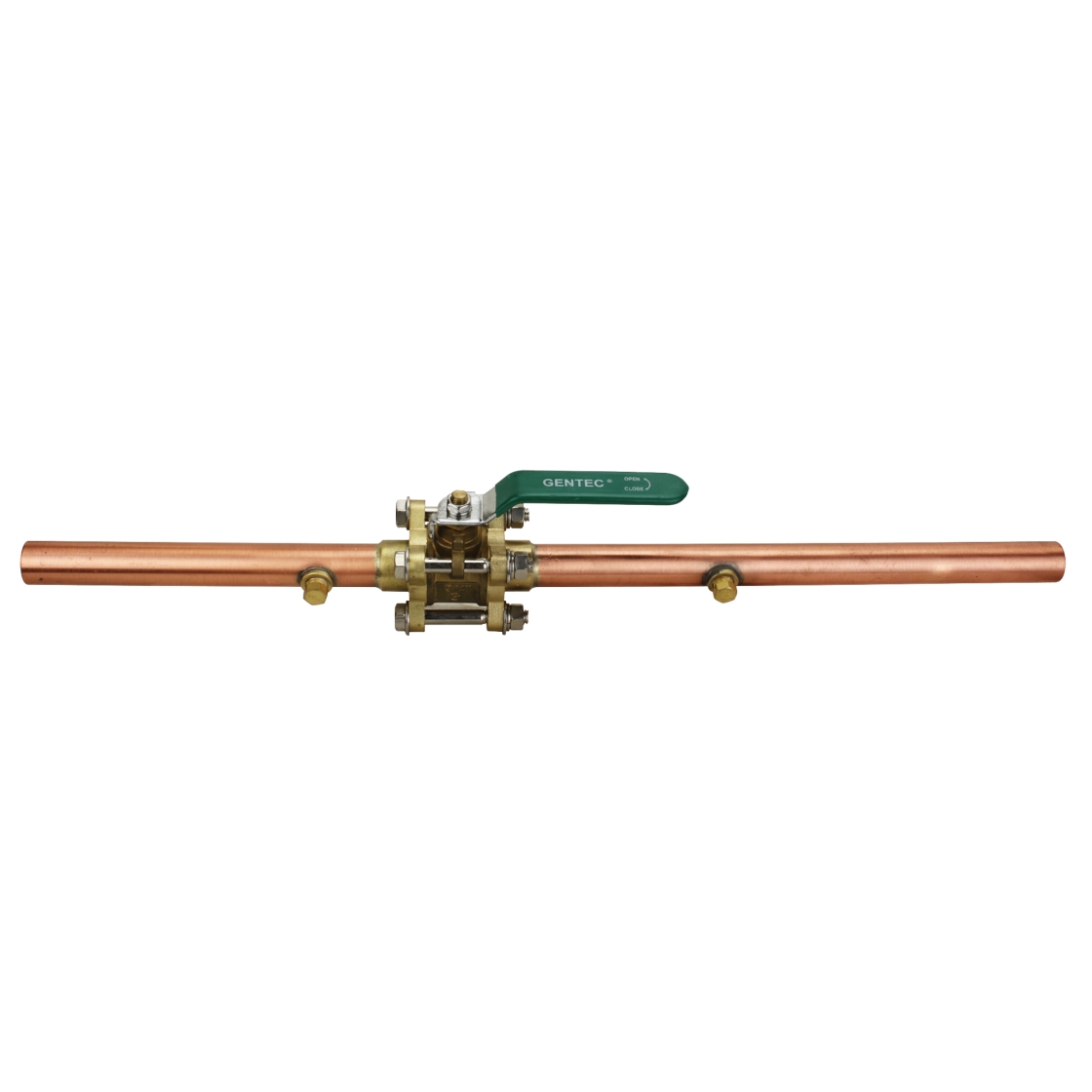

Dual Port Ball Valves

Ball valves are composed of double seal, three piece in-line serviceable ball-type design, with forged bronze/brass body and chrome-plated brass ball. Only 1/4 turn of the handle is required to operate the valve from a fully open to fully closed position. The valves have a full port design and incorporate an adjustable packing and a blow-out proof stem.

Ball valves shall be designed for working pressure up to 600 psig WOG. Valve body shall have Teflon® material ball seat and Teflon® material stem seals. Seats/seals, lubricants and valve materials are compatible with USP oxygen, nitrous oxide, medical air, carbon dioxide, helium, nitrogen and mixtures thereof at continuous pressure up to 600 psig and vacuum service to 29” Hg. Ball valves shall be provided with type-K copper tube extensions, for making connections to the pipeline and shall include dual gauge/purge ports sealed with brass HEX plugs. Locking or non-locking handles are available (locks furnished and installed by others).

All ball valves shall be supplied clean and prepared for oxygen service in accordance with current CGA G-4.1 standards. All valves shall be 100% tested for leaks and manufactured to comply with the latest edition of NFPA99. Valves shall be plugged and sealed in a polyethylene bag to keep them clean prior to installation.

Inquire about this product

Contact Us

Hours

Phone

Fax

Address

Chino, CA 91710, USA

Restrictions

![]() WARNING: Cancer and Reproductive Harm For more information go to www.P65Warnings.ca.gov

WARNING: Cancer and Reproductive Harm For more information go to www.P65Warnings.ca.gov